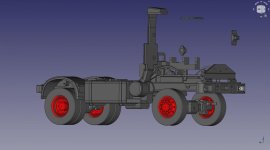

Frame, wheels and cab - Spring 2014 (1st part)

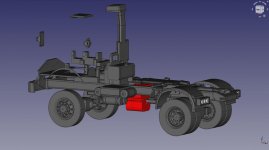

Since Tamiya makes the 1838 LS 4x2 it would have been easier to buy the model and add a driven axle to the front.

But since I had a 3D printer with too little to produce, I decided to try to build the truck by myself, self-producing as many pieces as possible.

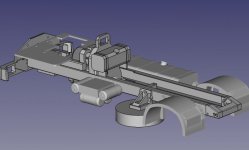

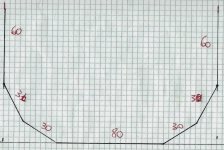

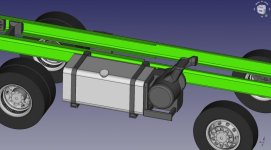

I started from the frame, cutting a steel "C" bar to size (40 cm) and creating the cross members with the 3D printer.

At this point I bought the whole cabin on eBay, in Japan (50 EURO shipped with all the pieces: front grill, windows,

etc.), which arrived in less than a week, incredible !!!!

Thanks to a friend, I was able to find two used TLT bridges, one of them was used for the front axle and the other remained as a spare.

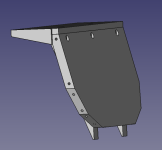

I printed the bumper (different from the Tamiya one which is for road vehicles) and the tilt for the cabin:

I ordered some tires like these:

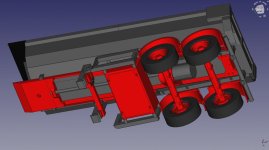

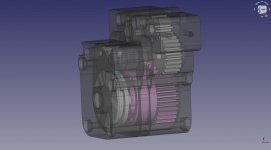

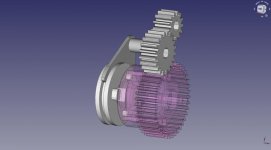

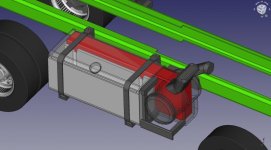

I also bought the rear axle and suspension from eBay. At first I wanted to build the leafspring by myself, using harmonic spring steel, but the first attempts did not go very well so I had to buy them. I wanted to stick to the original mechanics as closely as possible, so the idea was to insert a transfer case + reducer between the two axles and the top would have been to equip it with a real lockable differential (or at least a dig to disengage the front drive). I knew it was hard for my limite skills but....

After some days the rear axle and the leafsprings arrived.

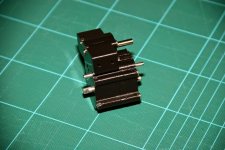

Now I had to find a way to put it all together. I printed some plates (very similar to the original Tamiya) to compensate for the curvature of the leafspring at the axle attachment.

The TLT bridge leaf spring holes are different from those of the trucks: I had to choose between making two new holes (on the other side they correspond) or I making an adapter plate ...

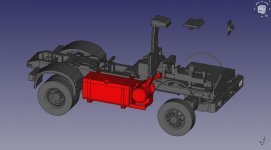

In the meantime I won in an eBay auction a Ford Aeromax chassis complete with almost everything (only the cabin is missing, to be honest) that I will cannibalize.

At the end, I drilled the TLT bridge with the column drill. Now it perfectly accepted the leafsprings. In the meantime, I did progress a little and the rear axle was finally attached:

A detail of the supports. The plates are made from an anodized aluminum "L" profile, further bent and drilled. I was not satisfied with the result, because the holes did not match perfectly, the edges were not the best, but I will had to settle wit it for the time being. The "biscuits" were derived from the old chain of my mountain bike.

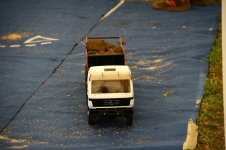

He was finally standing by itself on his wheels with the new tires (they arrived the same day )

Now at least it was a static (and mostly incomplete) model

), I fixed the various flaws and I added many features until it became as in the picture above (this picture was taken a couple of days ago).

), I fixed the various flaws and I added many features until it became as in the picture above (this picture was taken a couple of days ago).