Oscillating axle lock

It took me about the same time that I spent to project the whole excavator, to think/design/realize this single feature

The chassis had no more free space and I did not know how to lock the oscillating axle without making something unrealistic (like locking always in center position) or aesthetically unacettable....

I though it over for months and eventually I decided do go to real way: two hydraulic pistons over the axle and an hydraulic valve to block the oil flux when needed. Of course space was tiny to non-existent and I never realized hydraulics in my life.... This is the reason it took me about one full year to realize this last part.

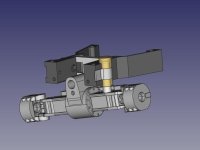

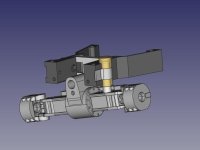

Once decided the design I started realizing the CAD project:

I found 12 mm of space between the chassis and the propeller shaft and I decided to use it for the valve and the actuator:

Then I realized the pistons and the attach to the main frame (this part was really hard to design and at the end I had to compromise a little)

The pistons have double O-ring and are made of chrome-plated ALU. Cylinders are 12 mm brass rods worked with lathe. Hydraulic connectors are 3mm from MAGOM.

The valve is actuated by an analog micro servo (EMAX ES08MA II) and is made of four parts: body, O-ring retainer, shaft and servo coupler:

I decided to use a compensating tank (first test showed that leakings are unavoidable

) so I needed a three way valve, ALL open and ALL closed. With axle unlocked it is possible to compensate leaking using the tank screw:

The M3 screw moves ahead the piston and insert more oil in the circuit. The brass gear keep the screw in position. Once empty it can be removed from its position and refilled like a syringe.

At this point, with my small CNC router , my 3Dprinter and the lathe, I realized the parts:

Realizing the valve was really difficult (for my reduced skills). There were a lot fo inside leaking and It did non work (initially) very well. I tried different approaches and materials and finally I found that brass body worked with a 5mm mill and stainless steel for the shaft worked best. I used 1.8mm O-ring of different diameters for everything this way I could use a lathe 2mm tool for every O-ring seat. The servo coupler was initially designed for CNC and made of brass/ALU. But the proto 3D part worked flawlessly so I decided to keep it and secure it with a 1.5mm rod.

After testing the whole lock for leaking I painted the new parts and mounted them on the chassis:

Everything worked more or less as expected ant FINALLY the axle does not collapse on the weight anymore

Last I realized the HMI Icon for my radio LUA script. Since I could not find anything in the CAD documentation I used a Volvo icon (Volvo wheeled excavators are really well documented on YouTube):

I updated the GitHub repo with the new parts, in case someone could be interested.

Luca72

.

.

) so I needed a three way valve, ALL open and ALL closed. With axle unlocked it is possible to compensate leaking using the tank screw:

) so I needed a three way valve, ALL open and ALL closed. With axle unlocked it is possible to compensate leaking using the tank screw: